Introduction

The restoration of ON1008 has been ongoing from virtually the first day we stepped aboard in December 2013 but has been gradual with the restrictions of time and money being the governing factors. Friends and relatives have generously given up their time on a number of occasions, without their help we’d not be at the stage we’re at today. To help with cataloguing the restoration here, we’ll write it up using the timeline as layout matrix, from 2013 to the present day 2021 where we find the boat in a sound operational order but still needing some elements of technical detail and cosmetic work completing over the coming years as time and funding allow.

Phase One December 2013 – July 2015

We first visited ON1008 where she had been marooned up on the shore for 13 years or so, near the village of Moross on the beautiful Fanad Peninsula in Co. Donegal, Ireland, in mid December 2013 along with our good friend Dr Rob Galvin (Marine Biologist) along with Colum and Amish Tom representing the group who owned the lifeboat, they kindly took us from Belfast International and later back for our return flight. On that first visit, during which a blizzard started and there was a cutting wind coming off the Atlantic we mainly were there to assess the potential of the boat and see if she was viable to rescue? First impressions on arrival at the boat were of general external neglect and smashed windows in the wheel house. Once we’d located a ladder and climbed aboard, it was very crunchy underfoot with broken glass all over the floor and it was additionally tricky walking too as the boat was leaning at 30 degrees to port! Some of the instruments had been damaged by the same individuals that had kindly smashed the windows too! We opened the bolt to the after cabin and although lined with pine and looking like a Scandinavian sauna it was, apart from two broken port hole glasses, in excellent order.

Next we unlocked the engine room and I was delighted to find that with the exception of a missing port side Airmax ventilator blower unit, a damaged thermometer on the starboard side and some messy wiring that all appeared to be in place. I’d already been advised by Quinton Nelson, the historic lifeboat expert and broker of this sale, that the engines weren’t seized and could be turned with the manual starting handles so at this stage we weren’t worried about them too much, that would come in 2014.

Moving forward into the fore cabin it was also secure and in pine clad splendour, we were slightly disappointed that the sea toilet (heads) was missing (a genuine ex RNLI Solent Class toilet was given to us by Derek Briggs in 2018 and is now restored awaiting plumbing in) but otherwise it was ok. We secured the engine room and aft cabin before setting about blocking the broken windows with plywood we found onsite. The original brass fittings for the broken starboard wheelhouse door sliding window were found on the floor so were popped them into a pocket as we realised they’d be damn hard to replace if lost!

We then had a good look around the outside of the boat, delightfully both propellors were in place, granted they were dull, chipped, dinged and with the odd piece missing on the tip, but at least they were present. The hull appeared to be generally very good with only a few small rust patches where the paint had been damaged, we couldn’t see the lower parts of the port side hull as it was sunk into the stones, gravel and sand of the beach. We found what was clearly the original navigator/radio operator’s chair dumped in the water to the left of the boat, I managed to pick that up and brought it into the wheelhouse which we then secured. This chair has since beeb fully restored.

Before leaving the Fanad Peninsula, we were taken to a local cottage where much of the original material and associated equipment was stored, we checked through it all and made a mental note of what was there. Then we were taken back to Belfast International Airport and flew back to Birmingham. Negotiations for the purchase, deposit and eventually final payments on the boat were all completed and then work had to begin, as well as working out how to get the boat back into the water when the time came.

February 2014

Next visit was during a break at work in February 2014 when Dr Rob and Callum drove over via the Cainryan to Larne ferry, quite a long journey from Birmingham. On arrival we needed to get a gas bottle for the heater we’d brought at the local shop run by Mary Galagher in Moross, we discovered that the fitting for the bottle didn’t fit our heater’s connector so we had to go back to the shop, Mary wasn’t sure but said she’d ask her son out the back on the farm, as we were strangers we had to wait outside the shop. On returning we got chatting and Mary realised that I had bought the lifeboat and that we were mutually acquainted with a couple of people, suddenly we were made very welcome and invited into the kitchen for cheese sandwiches and tea, the famous Irish hospitality!

Back on the boat we got the fire going which was very welcome as it was snowing outside, we had a couple of beers and made beds for the night, Callum had two wedge two air beds against the port wall of the aft cabin as the 30 degree list meant that he simply slid up against the wall regardless of what else he did!

The next day we fitted a battery we’d brought with us to the onboard 10kva diesel generator, much to our amazement and delight it fired up really and roared into life, all the lights coming on etc. On going out on deck it was raining, or so I thought but then we realised that the rain was black with soot and was in fact rain water being shot out of the exhaust system after filling it for many years! The previous owners had fitted the generator and devised what was a not ideal fan and ducting system to cool the generator in to the engine room, however for our needs this was an absolute boon as the air inside the boat was circulated and warmed most effectively. We seriously have little doubt that this kept us alive and working efficiently aboard the boat with freezing temperatures outside.

That first visit for two weeks was focused on clearing up broken glass in the wheelhouse and aft cabin, luckily we found a powerful vacuum cleaner on the boat that worked well (it still works now in 2021 with a new hose and reusable dust bag fitted, noisy but effective). We also made sure as best as we could that all the broken windows were temporarily replaced with plywood or aluminium plate to keep out intruders and with judicious use of gaffer tape all cracked glass was sealed against the elements too. We investigated as much of the boat as possible to explore what work was needed moving forward. It was noted that all the main battery banks had been removed due to the age and failure of the batteries from that dated from circa 1998, so ny now would have been 15 years old!

August 2014 – Re-launch

Due to the very limited access down the country lanes by Moross a crane or low loader couldn’t reach the lifeboat. Very likely had the access been possible the boat would have sold long before I was able to buy it! So the priority was to devise a methodology to get the boat back in the water and (hopefully!) afloat. Following that it would be a main focus to bring her back to life just enough to be sailed safely ideally under her own power to a location for a more thorough restoration to take place ashore. To that end Callum drove over to the Stenna Ferry from Birkenhead to Belfast in his 1991 Jaguar XJ40 that his uncle and aunty generously gave me for Christmas in 2008 (they’d owned it since 1994), he made sure I’d booked a cabin over on the ferry. Once over there Callum worked all the daylight hours preparing the boat for an attempted re launch on the mid August (12th) spring tide. After about 10 days of grafting and getting washed in a bucket he was a bit knackered. At tea time on the day before launching preparations were due to begin in earnest, the boat’s immediate neighbour and the local farmer Martin Sweeney popped down and said come to our house for a shower, have dinner and stay tonight if you like? Callum was very happy to accept this wonderful offer as to be honest he was pretty much, worn out, filthy and stinking, arguably at the end of his tether at that point! Callum still remembers with wonder that hot shower, it was magical and amazing, he’s sure it saved his life at that point, certainly his sanity (that’s debatable – ed)! The well charged gin and tonics that followed and subsequent superb dinner and company were exquisite as was a night in a comfy bed after all that time sleeping wedged in the corner of the floor of the after cabin, thanks guys!

We’d been attempting to devise all manner of clever methods of re-launching the lifeboat but as the tidal range there is very small, even the spring tide is not much more than a metre (3′) or so some help was going to be needed to get the boat off the shore and into the bay. We still had no working engines at this stage so couldn’t power off at all. One suggestion was to lay telegraph poles under the keel lubricated with banana skins – why banana skins we wondered? Then pull her sideways into the bay with straps around the local Moross Castle ruin . . . However it turned out to be a protected historic monument, so that was a no go even if we’d been able to source enough banana skins! Our launch budget was in retrospect naively tiny so ingenuity was needed, we couldn’t recourse to heavy lift helicopters or floating cranes, anyway the bay was too shallow close in for a floating crane and it is a very tricky navigation in from the Atlantic, through Mulroy Bay, into Broad Water and then up to the lifeboat in Moross Channel, even our very experienced RYA navigational instructor Jim Crick didn’t fancy planning a passage up there! In the end Martin Sweeny came to the rescue again and said look, stop feckin about, it’s a gravel and sand beach under the stones and I can get you a digger and driver for 400 euros if you’re interested? Also he added, I’ve arranged with the local Marine Harvest fish farm to bring their service vessel and pull you off the beach for free, that ok? Again absolutely marvellous! The digger and driver arrived the next day, Callum asked the driver what he thought we should do, he looked at Callum and said, “Sure I wouldn’t know, yer the man!”. Callum took a few breaths and composed himself to appear confident and knowledgeable of beach launching long marooned lifeboats . . . So asked him to dig a channel, about 4′ deep, at about 45 degrees out from there stern of the boat and into the bay, followed by a deep pool from the stern up to the halfway point on the port side of the hull. After he’d done that we finished for the day but the boat was leaning at like 50 degrees so it was decided there was no way Callum would be sleeping aboard and potentially find himself turned turtle in a 10′ deep pool! Callum slept (terribly) in the car and at dawn dared to peep out the window and there was the lifeboat standing steady, at a precarious angle grant you but steady, a joyous sight!

The digger driver arrived after breakfast and we directed him to dig a large channel on the starboard side of the boat along the whole length of the keel. This meant that the boat was now only sitting on a narrow pier of gravel and sand along the length of her keel. We now had to wait for the high tide in early afternoon. A small group of locals appeared to watch the re-launch, one of whom assured me that she was bound to turn over during the launch attempt, which didn’t in any way help to alleviate our stress levels!

At the allotted time the Marine Harvest service vessel appeared in the bay and a small boat brought the skipper and a substantial looking 2” diameter, light blue coloured, Polypropylene rope that was floating on the surface of the water all the way from the service vessel. The rope was attached to the aft keel pillar on the lifeboat and the skipper returned to the service vessel.

At a given signal the service boat pulled on the rope which zinged across the surface of the water shooting spray into the air and the lifeboat’s stern moved two feet to port. The service boat made a second run and this time the lifeboat stern turned out to sea, the gravel pier collapsed under the lifeboat and she slipped smoothly into the water and was heading at a good pace out to sea on a perfectly even keel!

We then ran around the small bay as fast as our wellies would allow, to a waiting fishing boat who took us out the lifeboat, Callum climbed determinedly aboard and then we towed her out to a large buoy attached to a one ton anchor block that Marine Harvest had kindly provided. The service vessel came alongside and with the aid of her hydraulic derrick, lifted the heavy anchor chain over the forward samson post of the lifeboat.

After appropriate gratitude was expressed, the boats all departed and Callum was left aboard on his own.

The first job on any newly launched vessel is obviously to check for leaks, the checksstarted in the fore cabin, all good, engine room, all good and then Callum lifted the hatch to the coolers and aft fuel tank compartment under the floor of the aft cabin and could clearly hear an ominous flow of trickling water sounding like a tap being run in a kitchen sink! This compartment of course is very cramped and inaccessible and the sound of running water was coming from the far end to starboard. He crawled my way through and eventually found that the water was flowing through a seam about halfway up one of two large square section posts that ran from the top of the compartment to the floor. At this stage he didn’t know what this square section post was (It later transpired that it was one of four scupper ducts that allow water to drain fast out of the wheelhouse should the boat capsize or take a wave through an open wheelhouse door) regardless, Callum knew that the leak was an urgent emergency that needed dealing with fast as there was no doubt that it could sink the boat quite rapidly if left to flow. Callum called his farmer friend Martin Sweeney and explained the situation and an hour later he appeared with a tube of black CT1, an amazing multipurpose sealant that will even set under water, he also brought some self-amalgamating tape that is used by plumbers to fix leaks on pipes. Callum crawled back into the cooler compartment and set to applying CT1 followed by wrapping self-amalgamating tape around the leaking seam on the ducting. He then applied more CT1 and wrapped layer upon layer of self-adhesive aluminium foil tape around the ducting until a thorough bandage was in place. This had much reduced the flow of water to a trickle but not stopped it entirely. Martin had brought a length of 1” rubber hose off the farm too so Callum rigged that up to a hand bilge pump (There were no 24 volt batteries onboard for bilge pump use at this stage, although the 240v generator could be used to power a pump if necessary) we had aboard and set up the hose to effect water extraction from the compartment, out through a broken porthole and over the side. Martin gave Callum a lift ashore in his Dory and we drove to the nearest boat yard at Downings by Mulroy Bay. We explained our dilemma and the owner told us that while there main slip was occupied with a large fishing boat, we were welcome to have the lifeboat towed round and moored on one side of the slipway at high water to allow a plate to be welded if necessary to cap off the ducting from below. Satisfied with that we returned to the boat and Martin dropped Callum off on board. Although now just a trickle the water was still building up in the compartment and required hand pumping out every 2 hours. Callum was was able to start doing other jobs on the boat in between pumping. At night he had to set his alarm every 2 hours to get up and pump out, his dreams as you can imagine focused largely on sinking ships! This pattern continued for a couple of days and then there was a marked reduction in water flow, presumably as the CT1 set more firmly. By this stage we had obtained a spare 12v car battery and was able to rig up a 12v bilge pump and automatic float switch we prudently had brought aboard. This set up was to work well for the following year and during this period the water ingress slowed exponentially as the weeks passed until eventually it effectively stopped. Callum spent another week or so alone (except for very welcome morning deliveries each day by Martin of fresh bread and milk) on the lifeboat during which he seemingly had to endure a gamut of fierce Atlantic gales that at times attempted to snap the anchor chain and as the boat had no means of propulsion, threatened to simply blow us back ashore once again! After that we returned to England to regroup and recover for a couple of weeks . . . Meanwhile as requested, the digger filled in all the channels and holes we had dug in the beach and there was no trace of where the lifeboat had been resting for all those years!

September 2014 – Afloat works, engine revival

For this trip over to Moross we took a hire van from Newbury and picked up Callum’s Mam and her husband David from Derry/Londonderry train station. Our great mate Dr Rob come with us in the van via Birkenhead to Glasgow on the Stena Line Ferry and later we picked up our other equally great mate Alastair Milne, a talented and very experienced communications electronic expert, although his talent for removing wood cladding in the wheelhouse was his main task on this visit!

Easter 2015

Callum came over with my sister Helen from Birkenhead to Belfast on the overnight Stenna ferry in their Dad’s old Peugeot 206, they hadn’t booked a cabin which was a big mistake as they had to endure a pair of morons getting increasingly pissed and talking ever greater bollocks as the hours dragged by! Sadly our Dad had died on May 10th 2014, after a period of illness at the age of 85 but we felt he was with us in spirit, certainly in the bottles of single malt we’d packed! Luckily Helen had booked a very nice old cottage on the Fanad Peninsula overlooking Lough Swilly, it was very cozy.

One critical job my Helen helped with was to fit the newly made 12mm laminated windscreen glass that we’d had custom made to suit the frame at Letterkenny Glass. The existing screen was smashed by vandals but in a way they’d done us a favour as the previous screen was only 4mm domestic glass, a disaster in the making that would have almost certainly shattered in a large wave or with a flying piece of debris!

On this visit to the boat afloat on the Moross Channel we were joined by our good friend and engineer Derek Briggs who over the course of a few days managed to help me get both of the magnificent Gardner 6LX engines running again. We had an issue with one injector of the starboard engine fuel pump but this was repaired with expert local help. We changed the engine oil on both engines at this stage too. A beautiful sound to hear the engines running again after they had lain dormant for well over a decade on the beach.

In July 2015, Callum and Derek arrived at the boat and were then joined by Daif Paine and Lee Benson, all good friends of Callum, we stayed in the fabulous Country Roads Inn at Rosnakill at night and prepared the boat during the day. She was readied for sea and a local pilot taken aboard. The sense of freedom and power of the Solent Class Lifeboat underway was exhilarating! We cruised down through Broadwater along the narrow navigable channel and into the next narrow passage, at this point the port engine overheated and stopped, luckily we were able to continue at a reduced speed and tied up to an anchor buoy near the fish farm. It was discovered that the port engine thermostat housing had become blocked with anti-freeze crystals, this was cleared and the water changed only to find on start up that the water pump bearing was now howling, seriously! We then had help from our friend Bernard who tracked down two bearings in Coleraine, they are an obsolete size! Relayed by Josey, owner of the Country Roads Inn, Daif and Callum sped to Coleraine in Dave’s powerful, 2 seat sports car, collected the bearings and returned to the boat. The bearing was fitted by the evening and after a few teething faults with the carbon water seal it settled down to merely the occasional drip. It was a howling gale that day so we were actually grateful for the delay in sailing out into the wild North Atlanti Ocean.

The next morning the pilot came aboard and we headed out across the Mulroy Bay Bar, the water was so shallow that at times we were able to observe the bottom clearly about 3 feet under our keel! The pilot wished us luck (“That you’re gonna need!” he said) and we were briefly on our own heading out to sea (next stop America!). Within minutes however we saw a little orange dot in the distance which turned into our mate Bernard Condon in the ex RNLI 47′ Watson Class Lifeboat, Joseph Soar. Bernard had sailed from Coleraine at 02.00 hrs to rendezvous with us at 09.00 hours and the tides to be with us. Bernard escorted us around Malin Head towards Portrush, both the voyage and the seas were smooth, in fact the Atlantic that day was utterly benign, large smooth swells easing J&MJ into a gentle rolling gait as she cruised faultlessly, we only had to ease off the revs slightly on the starboard engine to avoid a vibration spot caused by a damaged tip on the stbd propellor. Poor Derek our Chief Mechanic was afflicted with sea sickness after spending too long in the engine room, “coming out both ends” he groaned bless him! At one stage with a running tide we saw a speed of 11 knots register on our hand held GPS device. This slowed as we passed Malin Head and made for Portrush. With Derek temporarily incapacitated Callum had to take over engine room duties Daif took the helm for much of the passage and was obviously enjoying himself as he regaled us with his rich baritone singing popular shanties in the Thrash Metal oeuvre, in particular those of the popular beat combo Metallica, rousing stuff indeed! Callum once again took command as we entered Portrush Harbour and tentatively eased J&MJ around two dog legs of yachts and moored up ahead of the current RNLI Severn Class Lifeboat there. A slight nudge against the customs gate with the rubber fender and we were securely moored. We filled the fuel tank, showed the RNLI Coxswain Dezzy and some of his crew around the boat before rushing to the shower block in the Portrush Harbour, man those showers were good! Afterwards we headed in our blazers to Princess Street for delightful Gin and Tonics followed by a fine buffet provided from our friends Richard and Lee of Causeway Boats and The Whiskey Lad respectively. We then headed to the Harbour Bar for an evening of celebration, somewhere in the course of the evening Dave lost his favourite bush hat that has never been seen since!

The next morning we sailed up the River Bann to Coleraine Harbour, a journey Callum had last taken with his dad on his ship MV Firethorn laden with coal from Blyth in Northumberland. The passage up the Bann was fine but we had to keep the helm ready for swift action to counter occasional unexpected currents that would try to spin 48’6″ and 28 tons of ex RNLI Lifeboat around like a toy boat in a bath. We arrived upriver at Coleraine Harbour through the railway bridge, opened up especially for us and secured up safely at the quay. Our good friend Martin Strawbridge took a series of excellent documentary photos in Portrush and Coleraine on those two days, some of which he has kindly let us post here!

We left the next day as Callum had to get over to México for the first stage of his wedding to his then girlfriend Valentina. Bernard, Richard and Connor kindly took J&MJ upriver to the slipway for us later in July once the Harbour team had returned from their traditional ummer fortnight break.

Once ON1008 was safely ashore on the hard standing at Coleraine Harbour in July 2015 we commenced cleaning the hull and any needle gunning clean any associated rust spots where the anti-foul had failed during the 14 years the was up on the shore at Moross. Impressively though she had survived the ordeal in very good condition, a testament to the quality of her full lower hull refinishing in 1998.

Both propellors were damaged we guess from attempts to get her off the shore when she first was blown there by the storm surge, luckily we were able to buy a spare pair of perfect propellors taken from 48’6″ Oakley MK2, ON1016, 48-13, “Princess Marina” which had ben in storage after she was broken up at Portishead in 2003. These props are identical and were a straight swap once we’d made a simple tool to pull the original props off, they came off very easily. The originals will eventually be repaired as funds permit so we have good spares available should we ever need them.

Whilst outside for 2 years work continued apace on ON1008, including removing all the dreadful tongue and groove lining, insulation and other very crudely applied “improvements” inside the wheelhouse and floor of the aft cabin. Many of the boat’s essential electrical systems had been covered up and panelled in including some of the engine gauges, so all these had to be traced, repaired and replaced as required to bring them back to full operational status. Sadly the boat’s original builders plate was missing under the panelling as was the ships clock but we did find her ON1008 cast plate in a bucket of bolts which was a good find.

In the wheelhouse roof all the original windows had been removed and two huge 1/4″ marine grade aluminium plates bolted in place with a massive and roughly welded fixed mast above that, all these and the hundreds of bolts holding them had to be removed, then the roof windows removed from the side of the superstructure and fitted back into the correct position on the roof, this took hundreds of hours particularly as we had to source the missing port holes for the superstructure and have custom marine grade alloy plates CNC made to fit the portholes into. We were lucky enough to buy the correct ex Oakley 48’6″ portholes from a variety of sources until we had the full compliment required. In the rear wall of the aft cabin, rather than return to the original blank wall we decided to fit an opening ex Thames Barge bronze port hole which gives welcome extra light and ventilation without needing to open the access hatch or to operate ventilation fans. The sliding wheelhouse 1/4 light windows were stripped and rebuilt with perspex “glass’ as the originals were all smashed by vandals when she was ashore, ditto the starboard door sliding window, luckily the original fittings were found on the wheelhouse floor amongst the broken glass! One aft wheelhouse window was smashed too so this was replaced by a perspex one. All the fitting of new fenestration was carried out once we were inside the shed at Coleraine Harbour as was the painting of the hull with Jotun marine paint, with Seaforce 60 commercial shipping grade anti-foul paint on the lower hull and repainting of the deck with Tecreate anti-slip paint.

The hideous carbuncle of a mass that we inherited with the boat having been removed, so we commissioned our good friend and fabricator of great skill, Neil Lamborne, to fabricate a replica of the original folding Solent mast in marine grade aluminium with provision to mount the T DF (Direction Finder) antennae set (kindly donated by our good friend Hugh Searle) too.

Steering System – The Solent Class Lifeboats were all equipped with a Mathway manual steering system, comprising of a large vertical helm (steering wheel) attached to a binnacle with a 90 degree bevel mechanism attached to a vertical shaft with universal joints running down through the binnacle stand and through the wheelhouse floor to a 90 degree bevel box that has a short shaft with a UJ running horizontally back to a watertight bearing in the aft engine room bulkhead, then another section of steering shaft goes through the fuel tank and heat exchanger compartment where it goes through a watertight bearing into the steering compartment onto a section of shaft to a UJ onto the main steering bevel box. An arm on top of the steering bevel box is connected to the steering arm of the port rudder which is linked to the starboard rudder by a link arm. Both rudder shafts are supported by a combination of bronze thrust bearings and massive roller bearings before passing down through a bronze stern type tube sealed with a packing gland and are set directly into the spade rudders beneath. Originally the rudders were simply vertical spades but in practice the manoeuvrability was found to be disappointing so the rudders were extended with a an oval horizontal plate above and below (see photo in following gallery images). When we bought ON1008 the original Mathway steering system had been largely removed and replaced by a modern hydraulic system culminating in an hydraulic ram operating on the rudder arms in the steering compartment. The original bronze binnacle was in place but as the wheelhouse had been raised an extra section comprising of aluminium double flanged cylindrical tube had been bolted on top of the existing binnacle and culminated in a functional but unsightly aluminium box construction that housed the hydraulic steering pump and to which the helm was attached and the Sestrel Compass above. On purchasing the boat the steering worked but was very stiff, we managed to get it functioning a bit better but it still took too much effort to be comfortable, however we used this set up for the voyage from Co. Donnegal to Portrush and thence up to Coleraine.

The plan was to ideally return an original Mathway steering system to the boat which was going to prove a challenge, however we had a bit of luck in 2014 when via Mark Raynes I was put in contact with Darren in Plymouth who had just stripped the whole Mathway steering system out of his Solent Class Lifeboat (ON1014, 48-011, The Three Sisters) and was converting to hydraulic. We struck a mutually beneficial deal whereby in exchange for our hydraulic ram and some cash we got the complete Mathway steering system from ON1014! We eventually took this all over to Coleraine and worked out how to fit it back into ON1008 but with the added requirement of raising the helm approximately 1 metre to suit the raised floor in the wheelhouse. The first piece of luck was that the parts from ON1014 included the complete binnacle pillar and the binnacle box. This was attached to the existing binnacle pillar on the boat with a custom made (and expensive) A4 stainless steel adaptor plate made to an exacting standard by the excellent Band Engineering. We had to extend the drive shaft from the binnacle 1 metre too, so one of the spare shafts was shortened to the correct length again by Bann Engineering. The next job was to remove all the hydraulic steering paraphernalia below the wheelhouse floor and fit the Mathway steering bevel box in place. Not quite as straight forward as simply bolting it in place as even though from the same design, each Solent Class Lifeboat was effectively hand built no two are identical in every detail, consequently we had to offer up the bevel box and adjust some of the mounting bolt holes before it could be finally fitted in place and the shaft from the binnacle above connected. Behind the bevel box is the longest of the steering shafts and this was precisely rebuilt using the correct parts from our spares stash and expertly welded by our fried and coded Welder Wally, he did a superb job. This mated up to the existing rear shaft section and steering gearbox still on the boat, it was a joy to see everything turning and the drop arm moving for the first time since the 1990s!

Next job and possibly one of the most technically challenging was to drop off and service each of the two massive rudder stocks. Each rudder was still very stiff at this stage so we knew it was going to be tough just to get them out, it was a really worrying time as we’ve always struggled with the budget during the restoration as it’s always come out of our savings and if the rudders were damaged we’d likely have simply ground to a halt financially. A special and huge spanner was bought to remove the top securing nut on each rudder stock, then it was question of carefully working out how the sequence of bronze thrust bearings, roller bearings, keyways and mounting plates came apart. Then the sealing glands for each rudder tube were removed. We started on the starboard rudder first and it was an absolute bastard to get out, a day with wedges, heat and portable presses eventually got it out to much celebrating. The irony was that after a quick hone in the bronze rudder tube the rudder would slip in easily and turn freely, approximately 1/4 inch of oxidation at the bottom of the rudder tube was gripping it like a clamp! We did the same with the port rudder although that nearly caught us out as after just moving out about 1/4″ it just dropped out, luckily we had built up wooden blocks so it could only drop a couple of inches. The rudders are really heavy and it takes two people to ease them down to the ground safely! Once both rudders were out we replaced sections of the horizontal plates with new 1/4″ Corten Steel and welded it into place, new anode bolts were welded on and the stocks greased before lifting the rudders back in place and securing once new packing had been fitted to to each sealing gland and both of the massive roller bearings had been stripped, cleaned and reassembled with grease. one back in place, each rudder could be moved with the pressure of one finger, an absolute joy! The original drop arm and connecting rod were reattached to the rudder arms in the steering compartment and we once gain had a fully operational Mathway steering system on ON1008 as the RNLI Chief Architect had intended back in 1967!

After much work J&MJ was finally re-launched in September 2020 and was last worked on (beyond much appreciated essential maintenance by Bernard) by Callum in January 2020. Covid literally locked J&MJ down in Coleraine from March 2020 to date (May 2021), scuppering our passage plans for that year. We are determined to make our passage to Cornwall in August 2021.

There are masses more details of the restoration to add here which we will do gradually as time permits.

Serviced rudders replaced on ON1008 in 2017

Servicing rudders on ON1008 in 2017

Callum working on ON1008 in the shed at Coleraine Harbour 2018

Working on the rudders with a specially sourced spanner

Restored propeller access plugs

Measuring the original RNLI paintwork on ON1008 before repainting

Starboard wave subduer oil jet on ON1008, kindly donated by the new owner of 52′ Barnett Class Lifeboat, “John Gellatly Hindeman”

Jake Bowie installing historic RNLI flag decals on the bow of ON1008

Original Solent Class Baby Blakes Sea Toilet

A selection of nos original switches for ON1008, aircraft specification

The starboard 24v engine room Airmax ventilation fan on ON1008. We are looking for an identical unit that is missing on the port side.

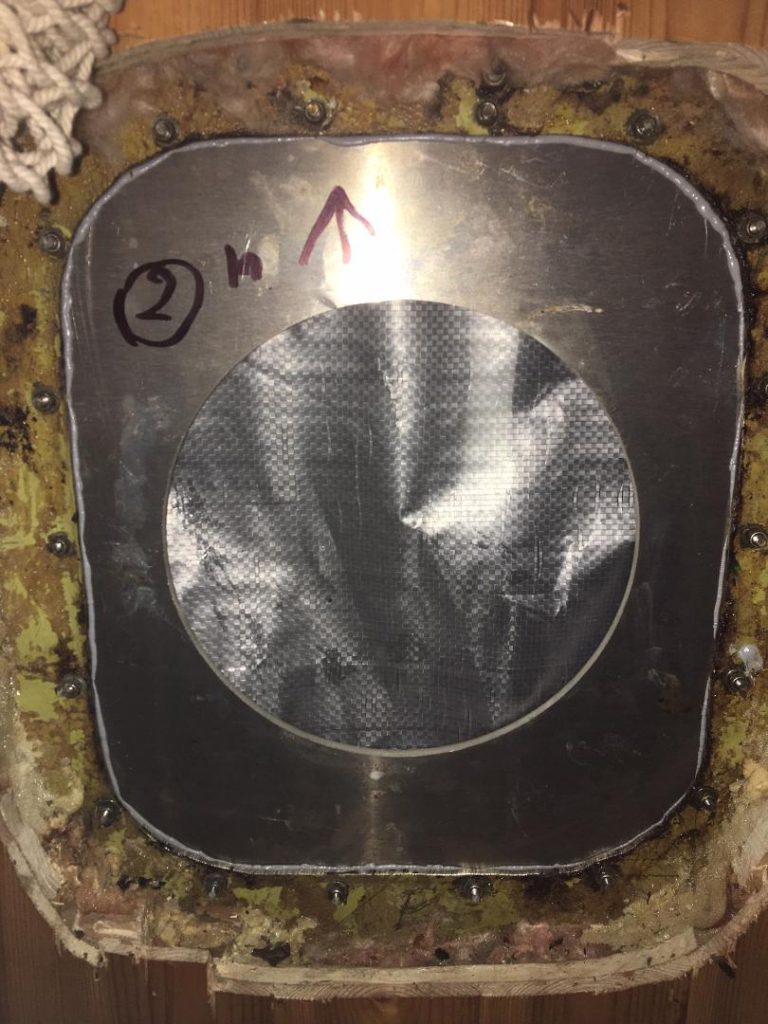

One of the new CNC cut marine grade plates to return the original aft and forecabins

Restored original RNLI porthole fitted to the new CNC plate on ON1008

Cleaning the wheelhouse roof before reinstalling the roof light windows

Cleaning the wheelhouse roof before reinstalling the roof light windows

Fixing the nose rubber protective steel fairing in 2019

On the way to relaunching in September 2019

Port 1/4 wheelhouse window, the old paint removed, stainless steel set screws removed, new fixed and sliding glass fitted then window rebuilt, original fittings saved and reused.

Dave and Christina hard at work during their time helping with ON1008’s refit in September 2019

Cleaning off and priming the keel in 2015 at Coleraine

Original restored Marconi Intercom for ON1008

Sizing up the final connection on the refitted Mathway steering shaft in September 2019

Excellent quality welding during the fitting of the original Mathway steering system to ON1008 in September 2019

Collecting a set of original Solent Class Mathway steering components from Darren in Plymouth 2014

Collecting parts for ON1008 form Scott Snowling at Lowestoft in 2017

Rob and Wrighty working on ON1008 in 2019 following hull painting

Inside of ON1008 wheelhouse during the fitting of aluminium platform panels August 2019

Inside of ON1008 wheelhouse during the fitting of aluminium platform panels August 2019

Inside of ON1008 wheelhouse January 2020

Replica RNLI crest fitted to ON1008 after enamelling and gold leafing January 2020

Inside of ON1008 wheelhouse during the fitting of Treadmaster to platform in August 2019

Looking up from well of wheelhouse to the roof of ON1008 in 2019

A replacement for the missing clock on ON1008, this was obtained in 2015 and was formerly fitted to a 1940’s French fishing boat

A replacement for the missing clock on ON1008, this was obtained in 2015 and was formerly fitted to a 1940’s French fishing boat. After servicing this is working really well.

ON1008’s original Radio Operators chair during restoration in August 2019

ON1008’s original Radio Operators chair during restoration in August 2019

Laser cut marine grade alloy plate fitted to aft cabin back bulkhead and ex Thames Barge bronze opening porthole fitted to that.

New updated fire fighting equipment as supplied in September 2019

ON1008 new starboard dash panel being fitted in 2019

The prop inspection moon pools on ON1008